How can I Measure my Gas Struts, to find a replacement?Updated 4 years ago

Table of Contents

1. Measure the Extended Length

2. Measure the Retracted Length

3. Understand the Ending Types

Ensuring you have the right lift supports for your car is essential for your hoods, trunks and lift gates to work correctly. Knowing how to measure gas struts will help you make sure you get the right part for your vehicle.

At Lift Supports Depot, we want to make sure you get the right parts. When learning how to measure gas shocks, struts, and lift supports, there are several things to consider.

Measure the Extended Length

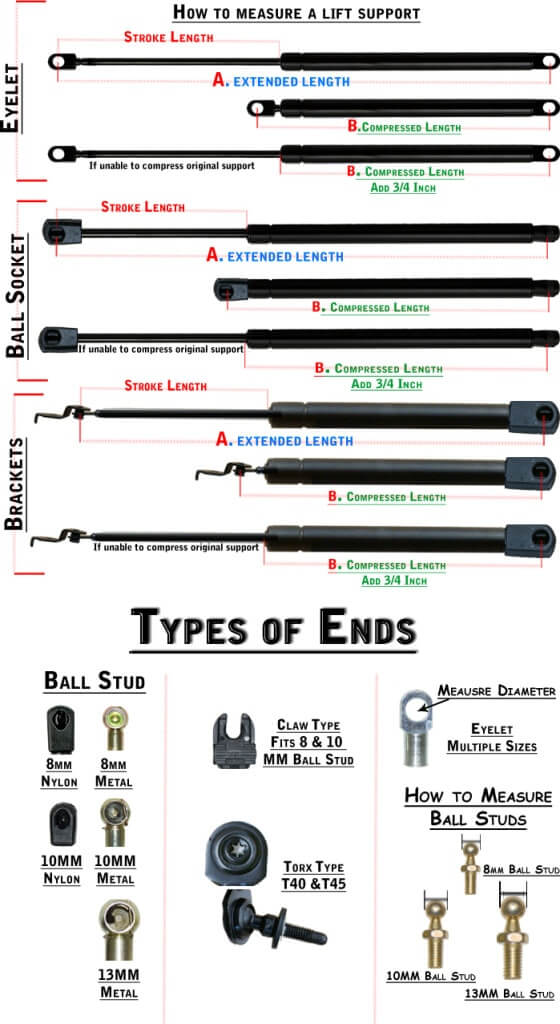

The extended length is the fully extended length of your support when measured from the center of the Ball Socket, Eyelet, or Rivet (if a bracket is used). Refer to the picture below marked with the letter "A.” Get the accurate measure of your gas struts.

Measure the Retracted Length

You also need to measure the retracted length, the complete collapsed length of the support measured from the center of the Ball Socket, Eyelet, or Rivet (if a bracket is used). In some cases, it is impossible to do this without removing the support. Therefore, we suggest you measure the body (not shaft) of the unit from the one end that the support has the Ball Socket, Eyelet, or Rivet (if a bracket is used) to the area where the shaft begins and add 3/4".

Refer to picture B-1 if you can collapse your support or B-2 if you can not compress the support.

Understand the Ending Types

When learning how to measure gas struts, it’s important to understand there are quite a few different types of ends used on lift supports. We’ll discuss a few of the most popular.

The most common size is a 10mm ball stud; however, 8mm, 13mm, and some 16mm ball studs are also used. Eyelets come in a wide variety of ranges as well and need to be measured across the end.

For uses that require a more secure end, the metal types are the best, and for any heavy weight lifting over 150lbs, 13mm types are strongly suggested.

Stroke Length

The last step in learning how to measure gas struts and shocks is to measure stroke length. The stroke length is the actual travel distance that the piston can travel. To determine stroke length, measure the exact shaft length on your existing unit.

This measurement is often overlooked; if it is too short, it will not allow the device you are using it on to close properly. In cases where you are not 100% sure, and if you have an old unit, you can place a rubber band on the shaft, close the device and measure the distance to where the rubber band has moved.

In the event that you do not have a metric measuring device, below are a few of the most popular conversions:

- 8mm = 5/16" = .32"

- 10mm = 3/8" = .39"

- 13mm = 1/2" = .50".

There are smartphone apps that will also do the metric conversions for you.

If you are new to learning how to measure your gas struts, we are here to help. We can build many different configurations, and if you can't find the lift support you need on our size selection chart, contact us and send us the details, and we will gladly quote you on your needs for measuring gas struts.

For your special projects, please keep in mind that we do not have a design staff, nor any qualified engineers or software to tell you what is suitable for your application. We have worked with individuals and have had great success. While it may take a little bit of trial and error, our goal is to work with you and help you with your needs. Feel free to send us a description of your needs, and we'll do our best to take care of you.